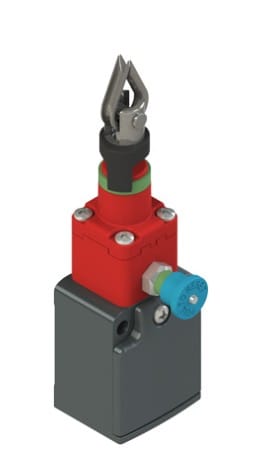

Pull Cord Switch

A pull cord switch, also known as a rope operated emergency switch, is a safety device commonly used in industrial settings, especially alongside conveyor belt systems.

- Home

- Products

- Pull Cord Switch

Let us help you

Pull Cord Switch

Pull cord switches, also known as rope-operated emergency stop switches, are safety-critical devices designed for conveyor systems and extended machinery layouts. They provide instant emergency shutdown capability across the entire length of the machine — all with a simple tug on a tensioned rope.

Unlike localized emergency stop buttons, pull cord switches offer linear access to safety, making them ideal for production lines, bulk material handling, packaging, and assembly environments.

Key Features

Emergency Stop Activation from Anywhere

Users can activate the switch by pulling the rope from any point along the installation — both left or right — enabling rapid response to hazards.

Wide Coverage

Supports rope spans of up to 70 meters, making it suitable for large conveyor installations or interconnected machines.

Manual Reset Systeme

After tripping, the system requires a physical reset at the switch — ensuring safety checks before reactivation.

Status Indication

Integrated mechanical indicators clearly show the switch status, helping operators monitor the line without guesswork.

Tension Monitoring

Built-in spring mechanisms detect rope slack, breakage, or over-tension, automatically triggering the stop circuit to ensure failsafe operation.

Robust Protection

Designed with high ingress protection ratings (typically IP65 or higher), suitable for dusty, humid, or industrial environments.

Fail-Safe Dual Contacts

Comes equipped with dual switching elements (usually 2NC/2NO) for safe signal isolation and control circuit feedback.

Typical Applications

- Conveyor belt systems in manufacturing and logistics

- Packaging and bottling lines

- Bulk material movement in cement, mining, and food industries

- Long machinery setups where multiple operators work simultaneously

- Warehouses with automated or semi-automated lines

Technical Specifications

Specification | Details |

Maximum Cable Length | Up to 70 meters |

Actuation Method | Bidirectional rope pull |

Reset Mechanism | Manual reset pushbutton or knob |

Contact Configuration | Typically 2NC + 2NO |

Housing Material | Industrial-grade metal or thermoplastic |

Mounting Options | Surface mount with rope tensioner kits |

Ingress Protection | IP65 or higher |

Operating Temperature | ‑25°C to +70°C |

Compliance Standards | Compatible with modern safety norms |

Installation Accessories (Optional)

- Steel or nylon rope

- Turnbuckles and tension adjusters

- Pulley wheels for rope direction change

- Eye bolts and brackets

- Signage and instruction plates

Ideal Applications:

- Packaging machinery

- Basic conveyor stop zones

- Agricultural machinery

- Textile lines

- Non-critical machine zones needing local stop access

Ideal for OEMs, Integrators, and End Users

Whether you’re designing a new conveyor system or retrofitting safety into existing machinery, pull cord switches offer cost-effective compliance, operator confidence, and zero-compromise safety for your facility.

Pull Cord Switches for Emergency Stop — Long-Range Safety Solutions

Pull cord switches, also known as rope-operated emergency stop switches, are safety-critical devices designed for emergency stopping of machines and conveyor systems. Unlike standard E-stop buttons, these switches can be activated from any point along a safety rope, offering full-length protection across the machine.

Widely used in industries such as manufacturing, packaging, mining, and logistics, pull cord switches provide operators with instant shutdown access, helping prevent accidents and damage in real-time.

Key Features

Emergency Stop at Any Point

Simply pulling the rope from either direction activates the emergency stop circuit.

Manual Reset Mechanism

Switches remain locked after activation until manually reset, ensuring equipment is not restarted unintentionally.

Visual Tension Indicator

Built-in tension window shows whether the rope is properly tightened. This helps maintenance teams monitor the system status easily.

Wide Coverage Range

Capable of securing spans up to 70 meters using a single switch, ideal for long conveyor or assembly lines.

Robust Construction

Available in both metal and technopolymer housings, designed to withstand harsh industrial environments. Protection rating up to IP67.

Flexible Mounting

Options for single or multiple conduit entries, vertical or horizontal actuation, and compatibility with M12 connectors or cable glands.

Technical Specifications

Parameter | Details |

Max Rope Length | Up to 70 meters |

Contact Configuration | 2NC, 1NO+1NC, 1NO+2NC, 3NC, etc. |

Operating Voltage | Up to 500V AC / 600V DC |

Thermal Current Rating | Up to 10 A |

Insulation Voltage | Up to 500 V |

Ingress Protection | IP67 |

Temperature Range (Standard) | –25°C to +80°C |

Extended Temp Option | –40°C to +80°C |

Mechanical Endurance | ≥ 100,000 cycles |

Electrical Standards | IEC 60947-5-1, EN ISO 13850, RoHS, etc. |

Applications

- Conveyor Systems in material handling, packaging, bottling, and cement plants

- Food and Pharma Lines with hygiene-grade versions

- Heavy Industries such as steel, mining, and power plants

- Cold Storage & Outdoor Equipment, thanks to extended temperature models

- Automated Assembly Lines with multiple operator zones

Why Use Pull Cord Switches?

Pull cord switches offer a simple yet highly effective solution for enhancing machine safety. They replace the need for multiple emergency buttons with one streamlined safety line, reduce installation costs, and meet strict international safety requirements. Their fail-safe design ensures machine shutdown not only during a pull but also in case of rope tension loss or breakage.

Accessories (Optional)

- Steel or nylon safety rope

- Tensioning kits and turnbuckles

- Pulley systems for redirection

- Eye bolts and brackets

- Instructional labels and signage

Rope safety switch without reset for simple stop

This rope-operated control switch is designed for simple stop functions on machines or conveyor lines. It allows the operator to stop equipment by pulling a connected rope from any point along its length. Unlike safety-rated switches, this version does not require a reset and does not latch, making it ideal for non-critical operations where full safety certification is not necessary.

Once the rope is pulled, the switch immediately opens its contacts to stop the connected machine. When the rope is released or tension is restored, the switch automatically returns to its original state — ready for the next action.

Key Features

Automatic Reset (Spring Return)

No need for manual reset. The switch returns to its default position once the rope is released.

Bidirectional Activation

Pulling the rope in either direction will actuate the switch.

Compact Design

Small footprint for easy installation, even in tight spaces.

Integrated Cable Clamps

Pre-installed clamps make rope fixing quick and secure.

Visual Activation Indicator

An external red actuator shows the switch status clearly at a glance.

Technical Specifications

Parameter | Details |

Rope Activation Force | Approx. 50 N |

Contact Type | Snap action |

Contact Configuration | 1NO + 1NC (standard) |

Max Rated Voltage | 250V AC |

Rated Current | 6 A (resistive load) |

Insulation Voltage | 500 V |

Operating Temperature Range | –25°C to +80°C |

Ingress Protection | IP65 (with proper cable gland) |

Mechanical Durability | ≥ 1 million operations |

Body Material | Reinforced thermoplastic |

Mounting Position | Horizontal or vertical |

Rope Length Range | Recommended up to 20–30 meters |

Ideal Applications:

- Packaging machinery

- Basic conveyor stop zones

- Agricultural machinery

- Textile lines

- Non-critical machine zones needing local stop access

Rope safety switch without reset for simple stop

Safety Rope Switch: Reliable Stop for Industrial Applications

Ensure the safety of your machinery and personnel with this safety rope switch without reset, designed for simple and effective emergency stops. These robust rope-operated switches provide a reliable solution for shutting down machines or conveyor belts from any point along the rope, with any pull.

Key Features & Benefits

- Versatile Housing Options: Available in durable metal (FD, FL, FC, FM series) or reinforced technopolymer (FP, FR, FX series) housings, offering flexibility for various industrial environments.

- High Protection Degree: Boasting an IP67 protection degree, these devices are built to withstand the toughest environmental conditions, including immersion, ensuring reliable operation where maximum housing protection is required.

- Multiple Conduit Entries: Depending on the series, switches come with one, two, or three threaded conduit entries (M20x1.5 standard) for convenient installation.

- Variety of Contact Blocks: Choose from 7 available contact blocks , including configurations like 2NC , 1NO+1NC , 1NO+2NC , 3NC , and 2NO+1NC , all featuring slow action contacts.

- Vertical or Horizontal Actuation: Versions are available with either a longitudinal (head 79) or transversal (head 80) actuating head, providing adaptability to your specific application. The head can also be adjusted in

90∘ steps after removing four fastening screws.

- Gold-Plated Silver Contacts (Optional): Enhance reliability with optional silver contacts featuring 1 µm or 2.5 µm gold coating.

- Extended Temperature Range: Special versions are available for ambient operating temperatures from −40∘C up to +80∘C , making them suitable for extreme conditions such as cold stores and sterilizers.

- Self-Control Function with Rope Adjustment Indicator: These switches continuously monitor their correct functioning, signaling with the opening of contacts an eventual loosening or breaking of the rope. A green ring on heads 79 and 80 indicates the area of correct rope tightening. The installer simply tightens the rope until the black indicator is in the middle of this green area. If the rope tension becomes too high or too loose, causing the indicator to exit the green area, the electrical safety contacts will open.

- Reduced Actuating Force (Optional): On request, switches can be supplied with reduced hardness internal springs. The force required to actuate the switch can thereby be reduced without changing the actuating path of the electrical contacts. This is particularly advantageous for smaller spans, but must always make use of rope pulleys.

- International Approvals: These safety rope switches hold numerous quality marks and approvals, including CE, IMQ, UL, CCC, and EAC.

- High Safety Parameters: These switches achieve up to SIL 3 according to EN IEC 62061 and Performance Level (PL) e according to EN ISO 13849-1.

Technical Data Highlights

- Mechanical Endurance: 100,000 operating cycles.

- Mission Time: 20 years.

- Rated Insulation Voltage (Ui): 500 Vac, 600 Vdc (without connector).

- Thermal Current (Ith): 10 A (without connector).

- Compliance with Standards: Designed and manufactured in compliance with a wide range of international standards, including IEC 60947-5-1, IEC 60947-1, IEC 60204-1, EN ISO 14119, EN ISO 12100, IEC 60529, EN IEC 63000, UL 508, CSA C22.2 No. 14.

Applications

These safety rope switches are ideal for use on machines and conveyor belts where a simple and reliable emergency stop function is required from any point along the rope.

For more detailed information, including complete lists of possible combinations and approved products, please contact our technical department.

Rotating Beacon Lights: Traditional Warning Signals with Modern Performance

If you’re looking for traditional warning lights, explore our range of rotating beacon lights. These beacons can be surface-mounted horizontally or vertically, installed on a tube, or mounted magnetically. Available in a variety of colors, they rotate at a consistent speed, regardless of temperature or environmental conditions. Choose from our selection of best-selling products, made from durable, high-quality polycarbonate material.

360° Visibility with Rotating Beacon Lights

The rotating light of an LED rotating beacon ensures particularly good perception. Due to the rotating illumination of the individual LEDs, the warning light is perceived from all viewing angles. Thus, a wide radius can be covered for warning.

Our rotating beacon lights are available in red, yellow, orange, blue, green, or with a clear lens. Depending on the model, the rotating beacon can be combined with an audible signaling device to increase the signal effect.

Versatile Rotating LED Beacons

The rotating light function can be found in our LED multifunctional lights within various series. In addition to numerous other light functions, the rotating beacon light function is frequently used in multifunctional beacons. Multifunctional beacons are available as standard and high-performance variants and can display the rotating light function in two different patterns and at different rotation speeds. Additionally, some models can be combined with an audible base for enhanced signaling.

Certain multifunction beacons with a rotating light function are equipped with an M12 connector. This ensures quick and easy installation. The rotating beacon can be put into operation immediately thanks to the plug & play installation.

Rotating Light in Best Quality

Our commitment to quality engineering ensures all our signaling devices are developed and produced to high standards. For over a century, we have been the right partner for technically sophisticated product solutions.

We develop our signaling devices with current trends and developments in mind. For this reason, you will find particularly powerful LED rotating beacon lights in our portfolio, which are clearly perceptible even in bright sunlight. Explore more to learn about the technical advancements that have moved beyond traditional rotating mirror beacons.

Multifunctional Beacons with LED Technology: Versatility for Every Need

Our multifunctional beacons with LED technology provide a comprehensive range of operating modes. Depending on the model, a single beacon can display various functions: steady light, flashing light, strobe light, rotating light, and pulsating light. These multifunction lights are available as both surface-mounted and panel indicator lights, meeting protection standards up to IP66. They are crafted with the utmost precision.

Multifunctional Beacons: The All-Rounders Among Light Beacons

Multifunctional beacons offer the advantage that several functions can be covered by a single beacon, providing maximum flexibility for the user. When conditions change, the light function of the multifunction beacon can be adjusted quickly and easily, eliminating the need to purchase an additional signaling device.

Our LED multifunction lights can provide the following functions:

- Steady light

- Flashing light

- Strobe lights with different strobe patterns

- Rotating light

- Pulsating light

Depending on the model, this results in up to 15 different operating modes per beacon. Learn more about the individual beacon functions.

Advanced Multifunctional Beacons

New series of multifunctional beacons are available in standard and high-performance variants. The standard variant comes in both a high and compact lens design, while the high-performance variant is available in the high lens design. The number of internal LEDs varies by model. Both types of multifunction lights can display numerous modes. Functions like pulsating light, dimmable light, and rotating light are especially found in multifunction lights with a high dome.

Compact versions of these beacons can display several different flashing light functions in addition to steady light and strobe light.

Multifunctional Beacons with Steady/Flashing Light

Cubic multifunctional beacons are available in various sizes and can display both steady and flashing light functions. In combination with a compatible signal transmitter, the signaling beacon can be extended with an audible signal.

In addition to surface-mounted lights, you will also find multifunctional lights among our panel indicator lights. Our panel indicator lights can also display the steady and flashing light functions.

Quality and Innovation

We are dedicated to the manufacturing and production of high-quality and innovative devices. Our signaling devices are developed and produced with a long-standing tradition of excellence. Our products are available worldwide through our international distribution network.

Steady Beacons: Consistent Status Indication

Our steady beacons are the perfect solution to alert your workers when a machine requires servicing or refilling. Thanks to our unwavering commitment to high-quality production, you can rely on our steady beacons for consistent, long-lasting performance. These steady beacons can be surface-mounted or used as panel indicator lights, and they meet protection standards ranging from IP40 to IP67.

Efficient Status Indication with Steady Beacons

Increase the safety of your operations with our LED steady beacons. The continuous light of a light beacon can indicate the status of a machine or piece of equipment without attracting additional attention. Continuous warning lights are usually used when there is no high potential for danger. The signal often serves purely as an information signal. Based on the color of the light of a steady beacon, indications can be given as to what subsequent action is to be taken. This could be, for example, the repair or maintenance of a device. If a sudden need for increased attention arises, certain steady beacon models can change to another functional mode, such as flashing. The constant flashing of the beacon increases the signal effect and is thus perceived more quickly.

Multifunctional LED Steady Beacons

Our multifunctional beacons can display other lighting functions in addition to the standard continuous warning light functions, depending on the model. In the case of our steady beacons with additional functions like flashing light, the two light modes can be controlled externally. Some models additionally offer the possibility of combination with multi-tone sirens. Other beacon series can be optionally extended with an audible module.

Multicolor Steady Beacons for Function Monitoring

Among our steady beacons, you will also find models with color-changing LEDs. These beacons can display different colors depending on the operating status. Certain multicolor beacons can display seven different signal colors as a continuous warning light. Other products can also display various light patterns in addition to the steady beacon light: The continuous, flashing, and alternating light functions can be controlled via a DIP switch.

Steady Beacons as Panel Indicators and Surface Mounted Lights

Our models are available as panel indicator lights and surface mounted lights. State-of-the-art LED technology ensures a long service life and particularly high brightness through sophisticated

Multicolor Beacons: Dynamic Function Monitoring

Our multicolor beacons are ideal for function monitoring. With a multicolor light, you can alternately display the different statuses of machines and devices without the need for an additional signaling unit. These multicolor beacons are available as both surface-mounted and panel indicator lights. The IP protection ratings for our multicolor beacons range from IP40 to IP69. Companies around the world trust our extensive experience in signaling solutions.

LED Multicolor Beacons for Function Monitoring

Our multicolor beacons can display between two and seven different colors, depending on the specific model. With a single beacon, the multicolor function can alternate states without the need for another signaling device. The lenses of the multicolor beacon light are clear or milky and have color-changing, high-performance LEDs installed inside.

Multicolor Beacons with Steady Light Function

All our multicolor beacons can display the steady light function. Some models can also display the flashing light function. External control determines which color is to be displayed. These multicolor beacons are available as panel indicator lights as well as surface-mounted lights, making them suitable for a wide range of applications. Indicator lights are particularly suitable for control cabinet construction. Modular surface-mounted lights can be combined with different bases. When used with an audible base, the multicolored beacon lights can be supplemented with an audible signal. Thus, in addition to the lighting function, the audible signal can also be used to warn or announce a change of state.

One Beacon, Many Colors

The multicolor light produced by these devices enables the conveyance of specific messages or warnings, as different colors can represent different meanings or conditions. Whether it’s a flashing red for an emergency situation or a rotating combination of colors for general signaling purposes, multicolor beacons offer enhanced visibility and visual communication options. Some multicolor lights offer maximum flexibility, capable of displaying the seven most important signaling colors: Red, Yellow, Green, Blue, Clear, Magenta, and Turquoise. Certain panel indicator lights can display the colors red and green separately but also in a split fashion, meaning one half of the lens can shine red and the other half green. The latter variant is particularly space-saving. We are also happy to implement other color combinations for your special application. Each color is assigned a certain meaning and therefore a certain action.

Panel Indicator Lights: Clear Status at a Glance

Our panel indicator lights are perfect for displaying the operating status or possible malfunctions of equipment. They are mounted directly in control cabinets, control panels, or on robots and machines. We manufacture various models of panel mount LED indicators with steady lights, flashing lights, strobe lights, as well as multi-color lights. These small recessed lights have a very high signaling effect and can be easily mounted with a nut in a 22.5 mm drill hole. Our panel mount indicators are manufactured to the highest quality standards.

What is an Indicator Light?

Panel indicator lights are installed in control cabinets, control panels, or directly on a device, such as robots and other machines. The small indicator lights are designed to signal technical faults or to indicate the operating status. In most cases, panel indicator lights are usually installed by means of simple single-hole mounting (M22).

How to Install Panel Indicator Lights

When mounting panel indicators, a hole is first either drilled or punched. Then the indicator light is inserted through the hole with the thread and fastened with the nut. Most of our panel indicator lights require a drilled hole diameter of 22.5 mm for installation. The final step is to wire the fixture.

Small Indicator Light, Big Signal Effect

Our portfolio of indicator lights includes steady beacons, flashing beacons, beacon strobe lights, as well as multicolor beacons. Despite their small design, these panel mount lights achieve a very good signaling effect. Due to powerful LEDs inside the dome, signaling with these indicator lights is very effective. In addition, selected panel mount models are also available with an integrated panel buzzer.

Some small panel mount LED lights have an installation dimension of 22.5mm (M22) and are easy and uncomplicated to connect thanks to their screw-plug-in terminal.

In addition to panel indicator lights with LED technology, you will also find xenon flashing beacons in our portfolio.

Signal Lights of Highest Quality

We are dedicated to developing and producing products of the highest quality. Through our worldwide distribution network and international product certifications, our signal beacons are available in many countries around the world. Do not hesitate to contact us to find the right signaling device for your application.